Our company implements strict production process management.

1. process design: according to the characteristics of the product, manufacturing process engineers conduct process design, prepare process documents, and by the chief engineer review and approval.

2. quality control: according to the product process documents prepared by the process engineers, quality engineers make product inspection and control plan documents, and by the chief quality engineer review and approval. The production process shall be inspected, recorded and archived in accordance with the inspection control plan.

3. production management: we implement computer aided management. Through computer-aided management, effectively ensure that each production step goes according to the plan.

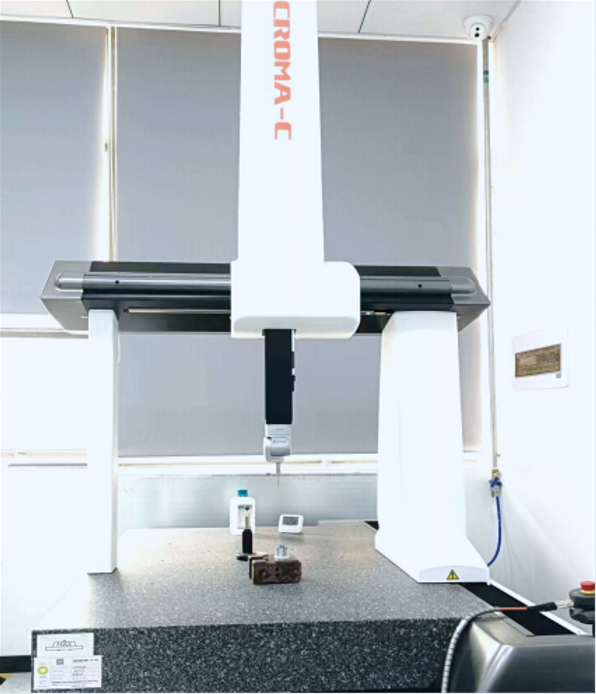

Our company is equipped with a comprehensive set of quality testing equipment and instruments, as well as a team of professional testing personnel to ensure product quality in terms of size, mechanical properties, material composition, and other aspects.Our main measuring instruments includes 2D smart scope, elongation tester, torsion tester, CMM, roughness tester, salt spray tester, RoHS tester and XR film thickness tester and hardness tester.

We have professional inspectors to complete reliable quality inspection tasks. Our main measuring instruments: 2D smart scope, elongation tester, torsion tester, CMM, roughness tester, salt spray tester, RoHS tester, XR film thickness tester and hardness tester.

| BRAND | TYPE | QTY. |

| VMS | Projector | 1 |

| ZHIQU | Pressure testing machine | 1 |

| Digital Torque Driver | Digital display torque meter | 1 |

| MP40E-S | Coating thickness gauge | 1 |

| SEREIN | Three-dimensional | 1 |

| Oertling | Salt spray tester | 1 |

| Laizhou Huayin | Rockwell hardness tester | 1 |

| JPSPEC | ROSH component tester | 1 |

Employees input real-time processing progress using mobile software, enabling visual tracking of each order's status. This significantly enhances production efficiency and reduces the risk of order delays.

Online work instructions and standardized operation procedures facilitate real-time recording of production process quality data and prompt entry of defective products, thereby enhancing quality management.

Efficiently connect upstream and downstream production teams to automatically notify the completion of tasks and push alarms in case of abnormal production. Real-time transparency in production dynamics makes management more efficient and convenient.

Monitor real-time production progress, understand personnel and equipment status, improve production efficiency, and enhance customer satisfaction.

In order to promote the safety production and environmental protection of metal forming industry, create a green enterprise, reflect the production concept of cherishing the environment and healthy come first policy, the company has adopted a series of energy saving and emission reduction measures:

Control Soot Emission: Formulate special environmental management programmes, implement effective monitoring tools, introduce new smoke and dust purification devices, and carry out strict acceptance and timely dynamic monitoring.

Prevent Oil Leakage: Modification of the hydraulic system, the use of new high-quality seals or have a good sealing function of the hydraulic valve, joints and other components to prevent oil leakage caused by pollution.

Centralized Processing of chips: Widely used chip dischargers, metal chips are discharged as soon as they are generated, collected centrally and disposed of properly.

Control Noise Pollution: Mufflers or throttling mufflers are widely used on the exhaust ports of gas distribution or directional valves, greatly reducing or even eliminating noise pollution.

Recycle of Waste oil: Mufflers or throttling mufflers are widely used on the exhaust ports of gas distribution or directional valves, greatly reducing or even eliminating noise pollution.