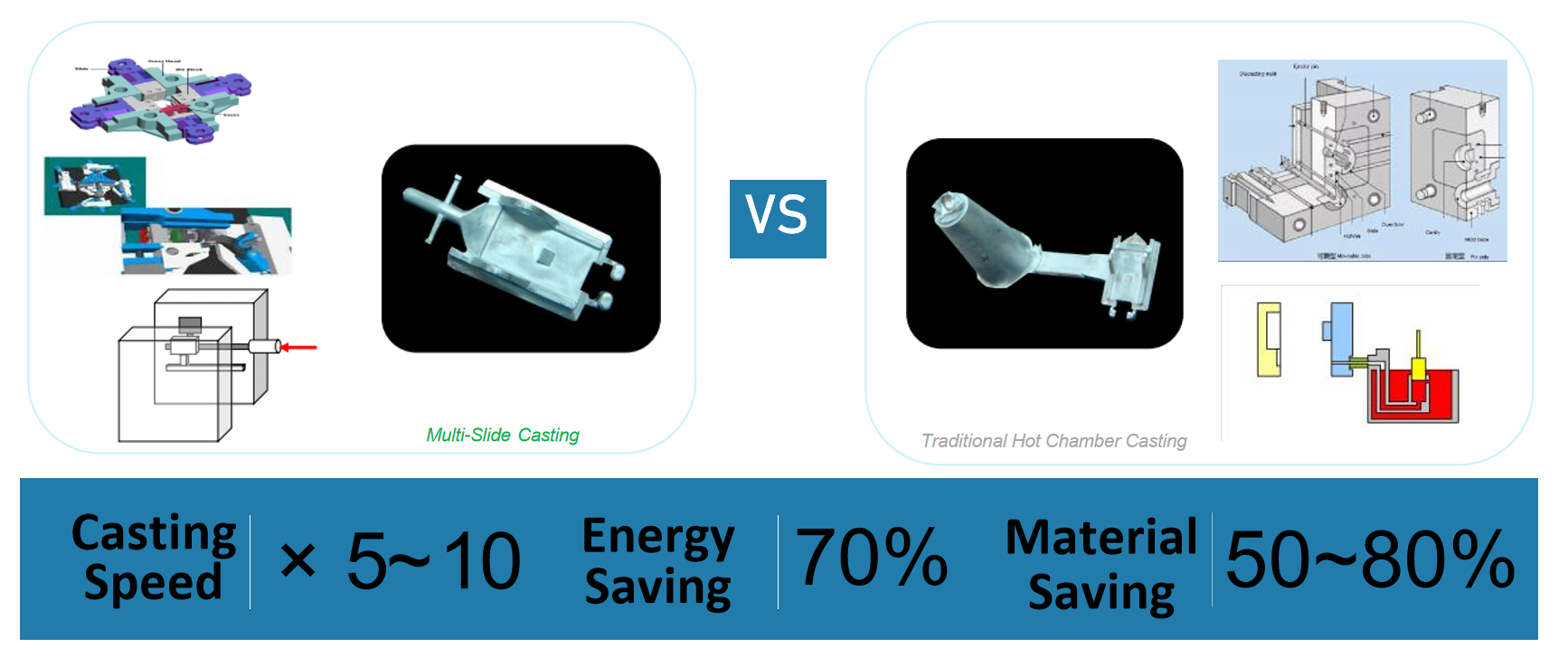

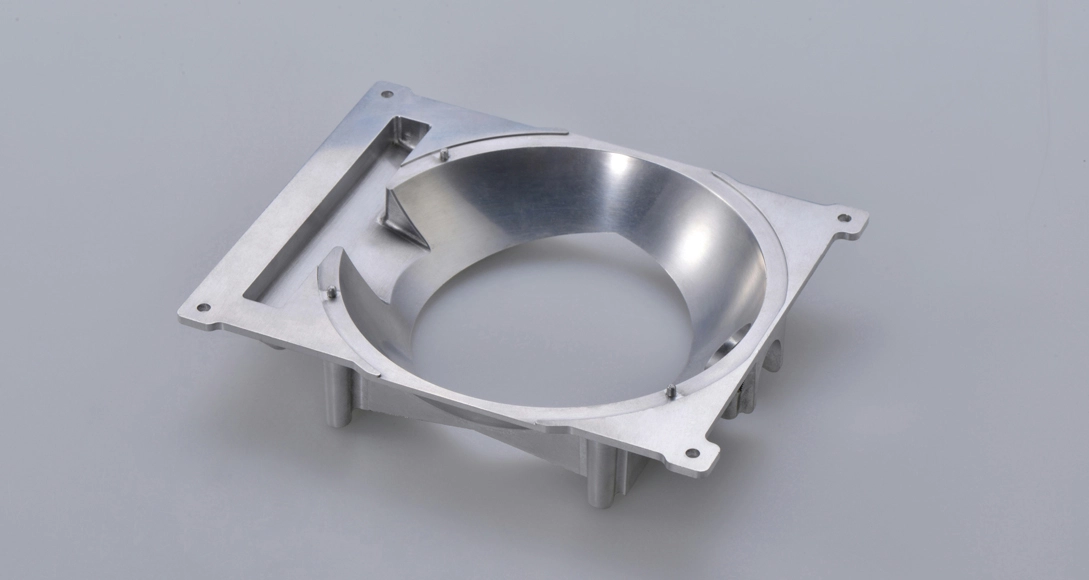

Multi-slide die casting technology is revolutionizing the manufacturing landscape by enabling the production of highly precise and intricate components. This advanced process utilizes multiple sliding tools that can move independently, allowing for the creation of complex geometries and tight tolerances, often as precise as 0.005mm. The multi-slide mechanism ensures that die inserts can be withdrawn from various angles, facilitating the production of parts with intricate details and minimal draft angles.

One of the key advantages of multi-slide die casting is its ability to produce near-net-shape parts, significantly reducing the need for secondary machining and finishing processes. This not only saves time but also lowers production costs. Additionally, the high repeatability and consistency of the process ensure that each part meets stringent quality standards, making it ideal for industries such as electronics, automotive, and medical devices.

The technology’s extended tooling life, often ranging from 1,000,000 to 1,500,000 shots, further enhances its cost-effectiveness by reducing the frequency of tool replacements and maintenance. Overall, multi-slide die casting offers a robust solution for achieving high precision in modern die cast manufacturing.

English

English