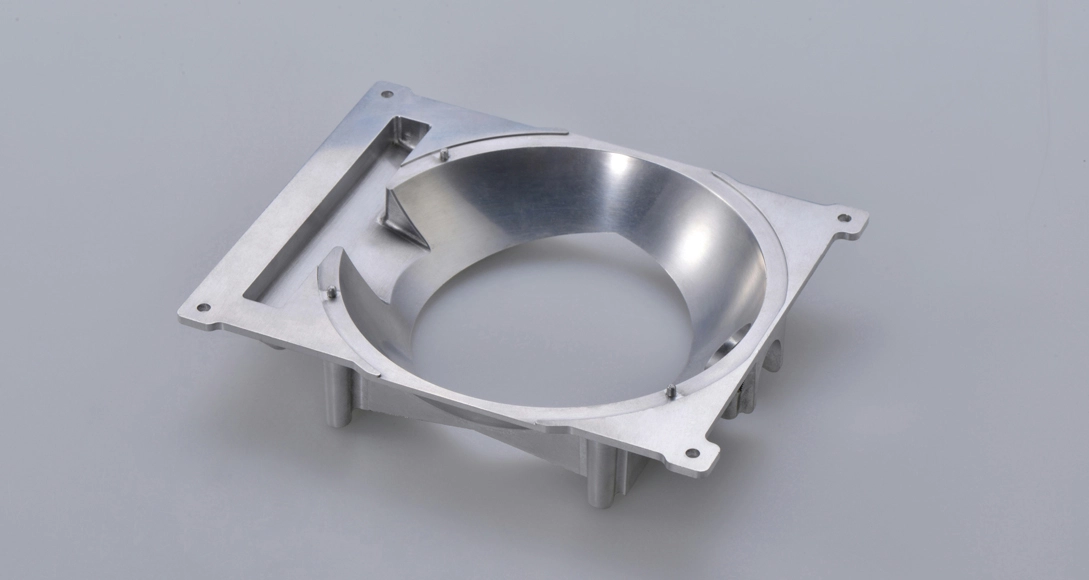

Zinc alloy die-casting machines are pivotal in producing high-strength, durable components for various industries, including automotive, aerospace, and consumer electronics. These machines utilize advanced technology to inject molten zinc alloys into precision-engineered molds under high pressure, ensuring the production of complex and intricate parts with exceptional accuracy.

One of the primary advantages of zinc alloy die-casting machines is their ability to create lightweight yet robust components. Zinc alloys offer an excellent strength-to-weight ratio, making them ideal for applications where weight reduction is crucial without compromising structural integrity. Additionally, zinc’s natural corrosion resistance enhances the longevity and reliability of the custom die cast parts.

Modern zinc alloy die-casting machines are equipped with features such as real-time monitoring, automated controls, and efficient cooling systems, which optimize the casting process and minimize defects. These advancements ensure consistent quality, high production efficiency, and reduced cycle times, making zinc alloy die-casting machines a cornerstone in the manufacturing of durable, high-performance components.

English

English